-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

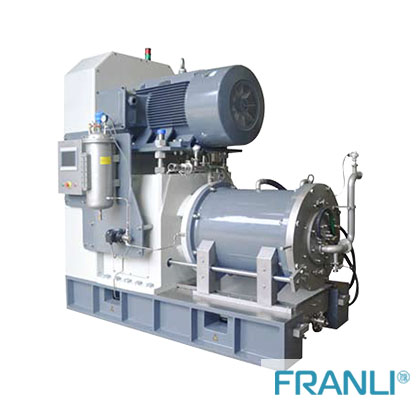

Bead Mill

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-siz...

-

Zirconia beads for sale|Zirconia beads price

Zirconia beads, also known as zirconia grinding balls, zirconia ceramic balls, zirconia beads, ultra...

-

Wet Bead Mill|Bead Mill For Sale

The wet bead milling we are selling is suitable for wet milling of a variety of materials, and wet b...

-

Sand Mill Machine|Sand Mill For Paint

The sand mill machine is a wet superfine grinding equipment, which is developed from the ball mill a...

-

Sand Mill|Wet Grinding Equipment Manufacturer

Sand Mill is the essential equipment in the paint, ink, and coating industries. It is designed to gr...

-

Bead Mill Machine

Bead mill machine is a microscopic and nanotechnology grind and dispersion device. The particulates ...

-

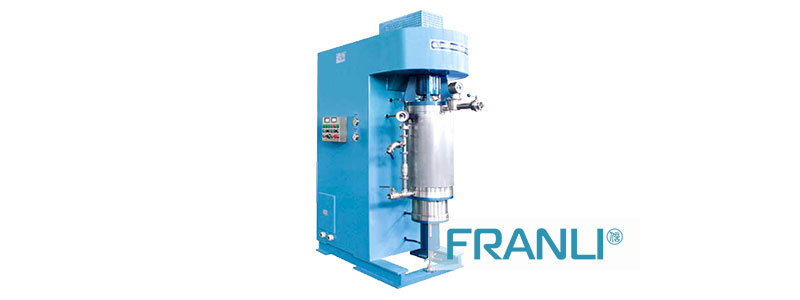

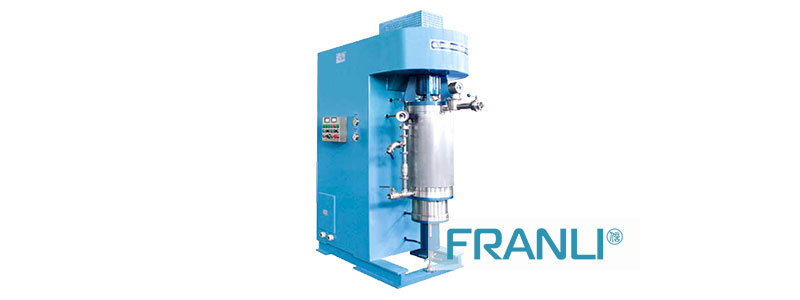

Vertical sand mill

Vertical sand mills are mainly used in batteries, digital consumables, ceramic materials, mineral pi...

-

Bead mill for paint

The application fields of liquid coatings are very wide, so a bead mill for grinding high-quality an...

-

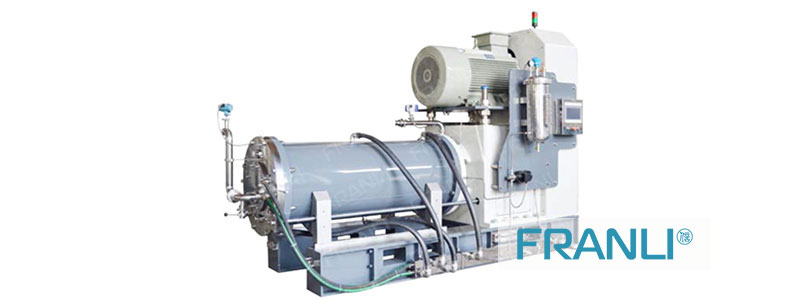

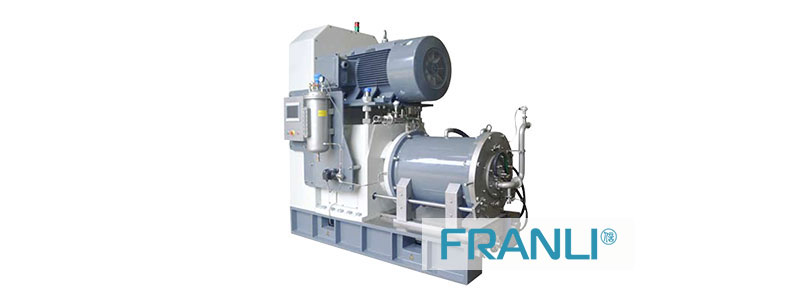

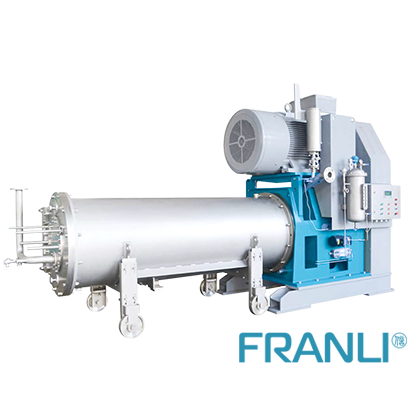

Horizontal sand mill

FRANLI's new horizontal sand mill has a complete grinding function, and far surpasses the traditiona...

-

Turbine bead mill

FLE turbine bead mill is a kind of nano mill, which is mainly used in medicine, food industry, agroc...

-

Lab bead mill

FLE Lab bead mill is widely used in coatings, inks, fuels, non-metallic mineral ultrafine powder, ma...

-

Nano Mill

Nano mills, as a kind of sand mills, are mainly for some small slurries, such as common inks and car...

PDF documents related to FLE BEAD MILL:![]()

Large Flow Bead Mill(sand mill) helps many factories to improve production. Grinding for low viscosity, well-flowing material. Self-cycling cooling system. Don't need the cooling pump. FLE produces Disc Bead Mill, Pin Bead mill, Turbine Nano Bead mill, etc. Optional material of inner chamber and disc: hardness Alloy, Zirconia, PU.

Bead Mill has safety arming when lower or higher pressure production, also arming for higher temperature, etc. Painting final size can reach 1-3um by two times in disc sand mill. If choose pin-type sand mill, higher efficiency, some material reach nano-size based on good price. Most bead mill has widely worked in the printing ink, digital ink, pesticides, lithium battery, painting, etc.

FLE Bead mill has worked in many different industries. Helping customers to get the more ideal final size, bright color, higher production capacity.

Welcome to connect with us, our engineer will support you to choose a suitable bead mill. Videos also showing the adjusting、working process, how to maintain bead mill. Which parts need check when starting grinding.

We are very glad to receive your samples for FREE testing material in our bead mill. Action now!

Disc Type Bead Mill

grinding material to reach1-5um for universal material, such as painting, ink, etc.

you can choose grinding beads size from 0.2mm-1mm for this type of bead mill.

the special shape of the disc, bigger outlet screen to reach higher production capacity. Which called high flow production horizontal bead mill.

Pin Type Bead Mill

Higher grinding effective than disc type bead mill.it can be cycling grinning by two/one tank

Pin type Bead Mill is a more powerful, well-controlled temperature.

Dyno bead Mill

Traditional horizontal bead mill, which outlet port at the middle of a bead mill.

working for pre-grinding, connect with the higher precise grinding bead mill. Two bead mill continues grinding increased efficiency.

Vertical bead Mill

Which is a Vertical traditional Bead mill. mostly working for pre-grinding for big size of raw material. the inner chamber can be SS or Alloy, according to with material. Chamber is connected with the chiller.

Lab Bead Mill

Pin or Disc Lab Bead Mill for small-batch grinding. 10kg material is enough for lab bead mill grinding. which type of bead mill is the same as a large flow bead mill. Easy operation, save space, fast cleaning.

Zirconia Beads for Bead Mill

Zirconia Beads size from 0.2mm, 0.4mm, 0.6mm, 0.8mm...2mm.

ZrO2: 95±0.2%, Y2O3: 5.0±0.2%.

Specific density(g/cm3)> 6.05.

Color: pure white.

We will offer quality certification for each batch of beads.

Best Quality Bead Mill Machine in China

FLE, we focus on the technology of the bead mill. Supporting and offering bead mills all over the world. We have different types of bead mills, such as disc-type bead mill, pin-type bead mill, nano bead mill, etc, also we have traditional dyno mill and per mill.

All bead mills specialize in grinding low viscosity material around 3000cps. We glad to choose the bead mill size and material of machine for your materials. Such as a PH7 higher material, you should choose ceramic (Zirconia) to anticorrosion. If you want to reduce the cost, then PU inner chamber is your best choice. PU and Zirconia material can corrosion prevention. While PU is more heating than zirconia, so if you choose PU material sand mill, pls choose a good chiller to control the temperature. Alloy material bead mill is universal also very popular in marketing.

Main replace parts: double sides mechanical, meters, beads, and some sealing rings. If you buy our machine, some of them can FREE for you.

We choose good reputation parts: ABB motor or Siemens motor, ABB VFD, NSK SKF bearings, Germany Burgman double side mechanical sealing, INGERSOLL pump, etc.

What are the key checking parts on the bead mill?

your operator should check the pressure meter when opening the bead mill slowly, then cool liquid pressure to check if leaking? During grinding, you can check material inlet pressure, temperature. If you have an auto full line, they should ask the factory to install a safety system with arming. If over the date, this machine should be stopped by itself.

About the Service, we offer you a 12-18month warranty for Bead Mill, Free testing by your material in our factory before giving us an order. Also, we FREE overseas training for your workers.

More about the Bead Mill:

| 1. | Advantages and operation methods of FLE bead mill |

| 2. | Selection tips for Bead Mill machines for the company |

| 3. | Bead mill for ink |

Advantages and operation methods of FLE bead mill

The FLE BEAD MILL is a machine for continuous superfine grinding and dispersing of solids in liquids. It works following the principle of agitator bead mills, where grinding media is accelerated in the grinding tank by an agitator shaft. The energy given to the media is passed onto the solid particles under collision and de-acceleration. Due to the tank being in a horizontal position, the special agitator gives an even activation of grinding media over the whole tank content.

The following advantages result from this:

1.high grinding capacity;

2.closer grain distribution;

3.less strain on the grinding system;

Bead Mill is fed in suspension and processed in one passage. The product flow is adjusted by the feed pump, which determines the residence time in the chamber and thus the fineness of the product. Machines with a variable drive system will allow the agitator shaft to rotate at infinitely adjustable speeds. Constant speed machines can also be adjusted by the use of different drive pulleys. Thus the bead mill can be adjusted to give the most efficient grinding for many different products over a very wide speed range. Depending upon the temperature behavior of the product the grinding chamber can either be cooled or heated.

Operation of bead mill

These operating instructions are designed to familiarize the user with the machine and its designated use.

The Bead mill contains important information on how to 0 operate the machine safely properly and most efficiently.

Observing these instructions helps to avoid danger, to reduce repair costs and down-times, and to increase the reliability and life of the machine. The instruction manual is to be supplemented by the respective national rules and regulations for accident prevention and environmental protection.

The operating instructions must always be available wherever the bead mill is in use and must be read and applied by any person who carries out works on the machine. In addition to the operating instructions and the mandatory rules and regulations for accident prevention and environmental protection in the country and place of use of the machine, the generally recognized technical rules for safe and proper working must also be observed.

Therefore we kindly ask you for your understanding that changes in the design or of the models of our product range may arise, that are reasonable for the buyer.

Please be advised that no essential change in the function will take place.

No claims can be derived from the illustrations and descriptions of this operating manual.

These operating instructions of the bead mill are only applicable to the order confirmation number stated on the cover sheet. This number can also be found on the bead mill nameplate.

Selection tips for Bead Mill machines for the company

Bead Mill is the best option to obtain the micro and nanoparticles of the materials. It contains advanced nanotechnology that grinds and disperses the material evenly with the help of shaft and shear force. The outlet of the grinding chamber includes a filtering structure that helps to separate beads particles. It is the best machine to get the fine production particles with the help of filters.

Also, you can get types of Bead Mill machines such as dry mill machines and wet mill machines. On the dry mill machine, you can get fine particles in the air or inert gas atmosphere. On the other hand, a wet mill machine is used to get liquid fine particles with the same procedure as the dry mill.

Some Selection Tips That Help You To Find The Best One:

You can install any one of them that meets all your requirements of the company. But, do you know? How to select the best mill machine that stays throughout your life? For this purpose, here are some selection tips that help you to find the best one for your company, and these are as follow:

● Select according to the budget: As we know, budget is the most powerful factor in performing the tasks of the company. It shows the financial condition of the company. In the market, several mill machines are available at different prices. Some are costly, and some are affordable. And, the ranges and the features also vary according to the price. So, it is up to you which one you choose. If your budget allows you to buy the cost, you can comfortably buy it and get started with all the grinding and dispersing activities of the company to increase production. In this way, you can buy the best and affordable bead mill machine for your company.

● Good quality rotating shaft: As we know, bead mill machines require a rotating shaft to move the grinding chamber to grind and disperse the material. Here, the quality of this shaft should be of best and robust so that you can handle the heavy-duty tasks effectively. And, the bead milling process needs so much energy so; try to get the Bead Mill that contains a sturdy shaft. In this way, you can get quality work and enhance the production of the company. Ultimately, always try to check the quality and durability of the mill machine to perform all the grinding tasks with full efficacy.

● Check the condition of the grinding chamber: While buying these mill machines, examine the quality of the grinding chamber as it is part of the bead milling process. If the condition of the grinding chamber is not up to date, how can you perform the grinding chores effectively? For this purpose, always buy that Bead Mill that contains robust and sturdy parts containing a grinding chamber. Therefore, buy the best quality mill machine to achieve your desired production level so that you can get the highest profitability ratio.

● Contains spot dust collector: When you look for the mill machines, try checking that it includes dust collector or not because it is the main factor of the bead mill working principle and where you can get the dust of the material. Thus, try to choose the best one for your company, so that you can increase the production rate of the company.

● Contains great quality separator: It is also an essential part of the bead mill working principle as it separates the beads and other particles of the material. For this purpose, you can check the sites of the bead mill manufacturers so that you can get the mill machine for your company to get the higher production rates. In this way, you can arrange the best Bead Mill machine to enhance the overall work performance of the company within the given time limits.

● Easy operation of the mill machine: When you purchase these mill machines try to check how to operate them. Well, bead mill manufacturers provide manuals along with the machine, and the operation is also so easy, But still, try to check before buying it so that you do not have to suffer your performance later. So, this step is necessary before getting these mill machines for your company as it is a matter of the production and profitability of the company.

● Obtains affordable mill machines: As we know, several automation companies offer these mill machines at different prices. And, if you are still worrying about the bead mill price, you can communicate with these companies as they offer these mill machines at affordable prices. You can search for these companies online and get bead grinding machine prices and other offers. So, now, you can get them at your desired prices and get started with them.

● Outer body should be sturdy and strong: If you have tremendous work to do, then the mill machine should be of the robust and best quality so that you can perform all the grinding tasks effectively without damaging them. When you looking for a bead grinding machine, try to check the quality of the inner as well as the outer body so that it can be easy to obtain the best results for the company.

Ultimately, when you buy a bead grinding machine for the company, you should keep these some useful tips in mind so that you can find the best and robust bead mill design for your company to get quality work performance.

In addition, FLE is the best automation company across the world known for its best quality mill machine and other equipment. It assures the durability and stability of the machines.

Conclusion: Mill machines are the best choice to perform all the grinding and dispersing tasks comfortably without adding much effort. So, do not worry about the bead mill price, just get them to enhance the productivity of your company as many companies offer them at affordable prices.

Also, bead mill design comes in various options, and you can choose according to your work performance to get the highest conversion ratio. Hence, getting these mill machines for your company is the best choice to enhance the overall performance.

What kind of ink you are producing?Offset ink, gravure ink, printing ink, digital ink, letterpress ink, packaging inkjet, industrial inkjet, commercial inkjet?If the ink is discharged statically.

For inks, the wear on the wearing parts will be less, because the viscosity of the ink itself is relatively high, the oil is oily, and the zirconium bead wear is relatively small.

Zirconia Beads

Zirconia Beads

If the zirconium beads are not strong enough, they are damaged during the grinding process, which is fatal to the dynamic discharge. The dynamic discharge is constantly rotating, which can easily jam the separator and damage the separator; if the separator is replaced, it will not If the zirconium beads are replaced or the zirconium beads are not carefully sieved, the broken beads of the zirconium beads will still exist, so the separator will still be stuck by the broken beads.

Nano Mill

Nano bead mill is a vertical type, which makes nanometers. The reason: not only the rod pins on the rotor but also on the cylinder, it’s perfect to use 0.2-0.3 beads for the bead mill.

Then our bead mill generally uses 0.2, 0.3mm, with static discharge, the screen is 0.3mm, if the beads are 0.2mm, the beads will run out, with 0.2mm beads, the processing accuracy of the bearing seat cannot be guaranteed. Bearings It is oily. In the process of operation, the coaxiality of the interbody is not so standard, so it is not acceptable to use 0.2-0.3mm beads. If the viscosity is low, use the meshless one, and the viscosity will be higher. Yes, it is necessary to bring a screen, the screen may use a gap of 0.05 or 0.1.

Lab Bead Mill

Lab Bead Mill

Cone bead mill

Cone bead mill is usually worked in offset ink, screen printing ink, offset printing ink.

Disadvantages: In the cylinder bead mill, the linear velocity is not uniform. The linear velocity of the big head is the highest. When the cone rotates, the linear velocity of the big head is the highest, and the smallest head is the lowest. So when selecting the line speed, Whichever is the highest or the lowest? Line speed has a set value in the industry

If you take the big head as the standard, the small head linear velocity will be too low, which means that this part of the solvent space is equal to waste, and the efficiency is low; if the small head is the standard, the big head is low, the linear velocity will be very high, which will cause wear Intensified, it will also cause the temperature to be too high.

The FLE BEAD MILL is a machine for continuous superfine grinding and dispersing of solids in liquids. It works following the principle of agitator bead mills, where grinding media is accelerated in the grinding tank by an agitator shaft. The energy given to the media is passed onto the solid particles under collision and de-acceleration. Due to the tank being in a horizontal position, the special agitator gives an even activation of grinding media over the whole tank content.

dyno mill

The following advantages result from this:

l high grinding capacity;

l closer grain distribution;

l less strain on the grinding system;

Bead Mill is fed in suspension and processed in one passage. The product flow is adjusted by the feed pump, which determines the residence time in the chamber and thus the fineness of the product. Machines with a variable drive system will allow the agitator shaft to rotate at infinitely adjustable speeds. Constant speed machines can also be adjusted by the use of different drive pulleys. Thus the bead mill can be adjusted to give the most efficient grinding for many different products over a very wide speed range. Depending upon the temperature behavior of the product the grinding chamber can either be cooled or heated.

Vertical bead Mill

Operation of bead mill

These operating instructions are designed to familiarize the user with the machine and its designated use.

The Bead mill contains important information on how to 0 operate the machine safely properly and most efficiently.

Observing these instructions helps to avoid danger, to reduce repair costs and down-times, and to increase the reliability and life of the machine. The instruction manual is to be supplemented by the respective national rules and regulations for accident prevention and environmental protection.

The operating instructions must always be available wherever the bead mill is in use and must be read and applied by any person who carries out works on the machine. In addition to the operating instructions and the mandatory rules and regulations for accident prevention and environmental protection in the country and place of use of the machine, the generally recognized technical rules for safe and proper working must also be observed.

Therefore we kindly ask you for your understanding that changes in the design or of the models of our product range may arise, that are reasonable for the buyer.

Please be advised that no essential change in the function will take place.

No claims can be derived from the illustrations and descriptions of this operating manual.

These operating instructions of the bead mill are only applicable to the order confirmation number stated on the cover sheet. This number can also be found on the bead mill nameplate.

Welcome to check our factory and testing machines by your materials.

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- What is the difference between dyno mill...

- Specification of high speed disperser an...

- What is a three roll mill machine?

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- How to operate High-Speed Disperser

- Faults and Trouble Shooting Methods of H...

- Advantages and operation methods of FLE ...

- How To Choose Vertical Bead Mill or Hori...

- Triple Roller Mill